Rident’s high quality standards are internationally recognized, and the credit certainly goes to our team of professionals in the sector that brings daily expertise, preparation and exceptional precision to meet the expectations of those who decide to smile with us again.

Rident Polyclinic has three Ridental dental laboratories, one in Rijeka next to the polyclinic, another one in Rijeka’s Srdoči neighborhood and one in the Poreč branch.

Daily lab activities include:

The dental lab produces all modern dental prosthetic replacements – including the production of crowns and bridges using the latest CAD / CAM technology and fully meets all medical, technical and aesthetic requirements, for a quality result that can make the patient happy.

The materials used in the production of prosthetic replacements were tested for cytotoxicity, irritation, sensitivity, acute systemic toxicity, chemo-compatibility and genotoxicity. All materials are rated as biocompatible, and all materials used are products of renowned global companies.

Each Ridental product comes with a declaration of conformity of the product in accordance with the health and safety requirements of the EU Regulation 2017/745 of the European Parliament and of the Council of 5 April 2017 on medical devices and in accordance with HRN EN ISO 13485:2016 (EN 13485:2016) and the Technical Map of Ridental Products.

We want to provide our patients with safe and reliable dental replacements, relying on globally known companies.

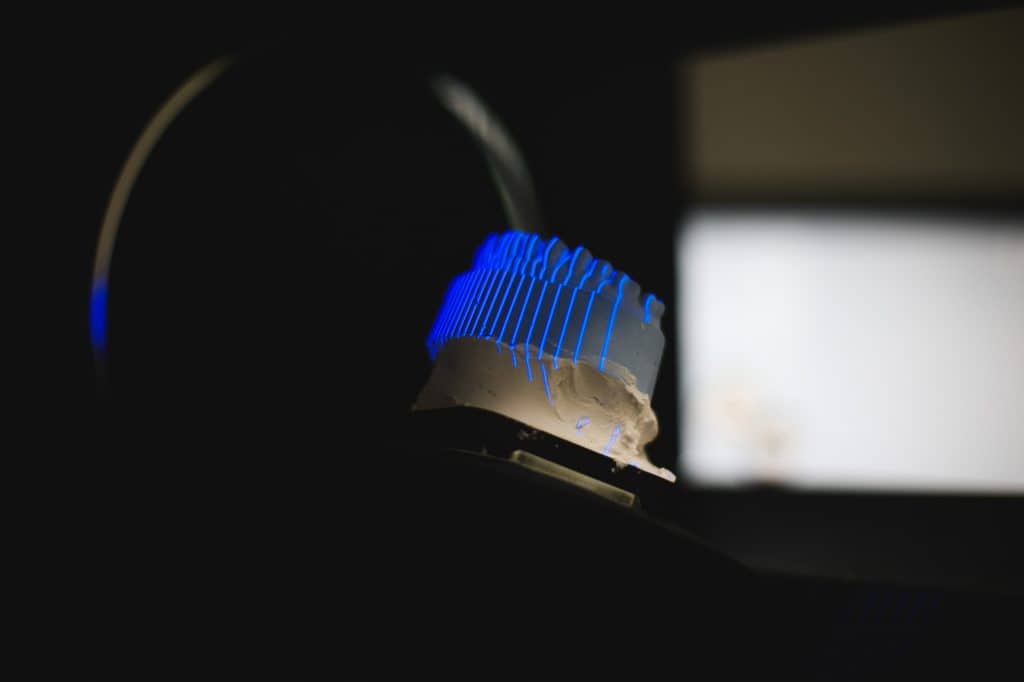

One of these companies is certainly BEGO, a German company that first introduced SLM technology in 2001, an acronym for Selective Laser Melting. This procedure involves layered fixing of the metal powder with the help of a laser.

This method fixes the metal powder layer by layer with a laser beam. The scanned situation in the oral cavity is transmitted digitally to the screen, while the dental technician then virtually models the construction. The three-dimensional data thus obtained is then converted into a two-dimensional cross-section, which the SLM machine applies layer by layer, thus creating a structure.